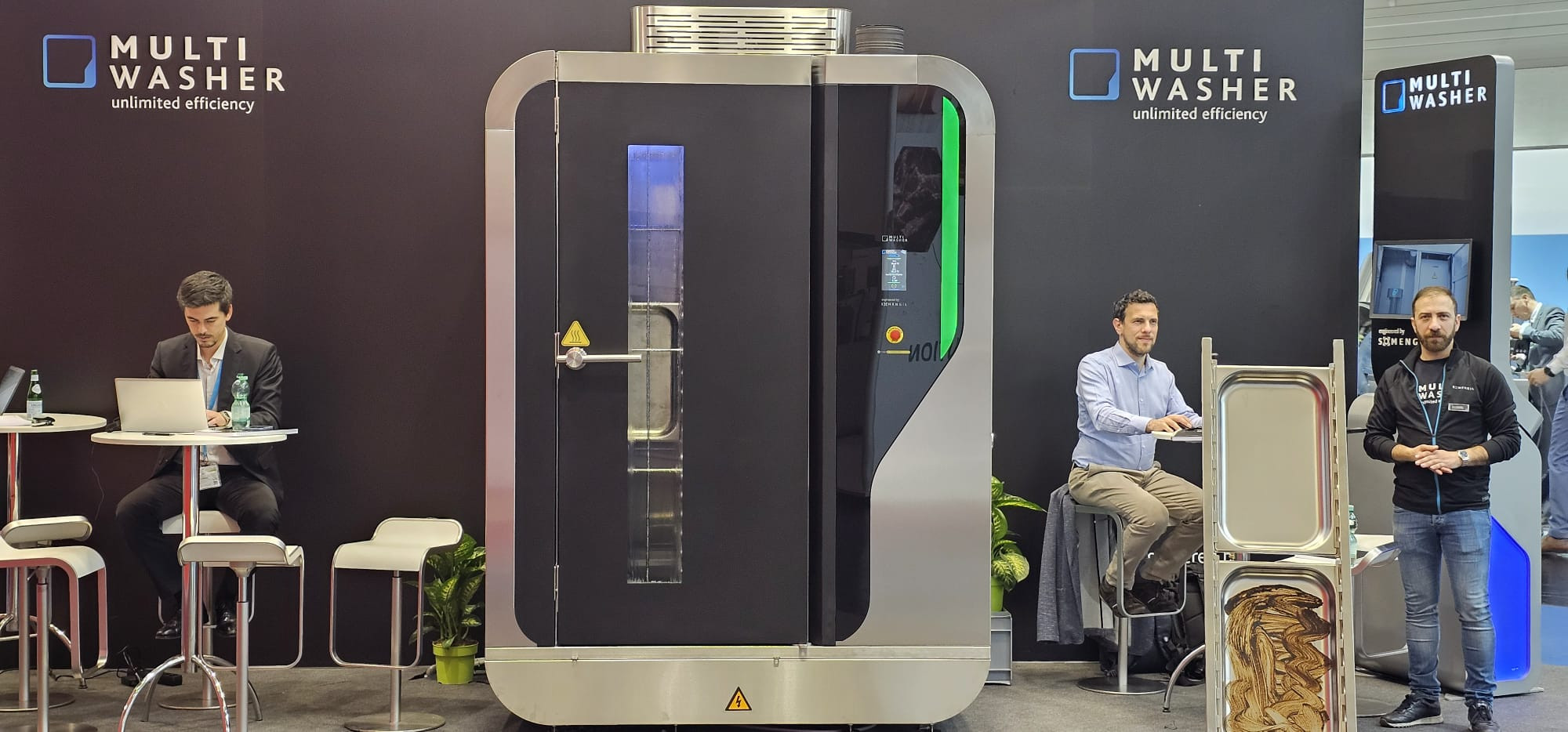

Innovative washing solutions

Multiwasher has been designed in a cabinet format, which allows for the complete control of washing processes.

Its state-of-the-art technology ensures efficient and sustainable washing, based on optimized processes that not only guarantee disinfection, but also save energy and resources.

Design and versatility

Multiwasher's versatility allows it to develop customisable solutions tailored to each customer. Various utensils and objects can be integrated into a single wash, allowing for greater flexibility.

Multiple industries

Multiwasher was developed to be an effective washing solution for any industry. Thanks to a system of trolleys and programmes tailored to what you need to wash, we guarantee quality and optimised washing.

They are with us

Join us too!

2,000 installations in more than 30 countries.

Our satisfied customers are proof that our hard work will give you the best experience. From the high level of competence of our engineers, through the consultative sales process, and ending with the installation and after-sales service, everything has been designed to give you the greatest satisfaction.

Portugal

Portugal United Kingdom

United Kingdom United States

United States France

France Spain

Spain Germany

Germany Romania

Romania Italy

Italy Czech Republic

Czech Republic Finland

Finland Hungary

Hungary Slovakia

Slovakia Greece

Greece Lithuania

Lithuania South Korea

South Korea Russia

Russia Saudi Arabia

Saudi Arabia Poland

Poland Brasil

Brasil Hebrew

Hebrew