Industrial washing / Articles

Utensils washing machine: how to choose a perfect fit for your company

Find out how to choose a utensils washing machine that saves time, keeps hygiene high, and fits your kitchen’s real workflow.

8 minutes of reading

8 minutes of reading

2026-01-22 13:00:06

In any busy kitchen or food production line, the pressure is relentless. Trays stack up faster than your team can wash them, trolleys wait in corners, and every minute of delay risks slowing down the entire operation.

The right machine can do more than wash. It can transform workflow, reduce stress, and ensure every tool is ready when needed. Getting this choice wrong, however, can cost time, money, and peace of mind, every single day.

Discover how a carefully chosen utensils washing machine can maintain top hygiene standards and give your staff the confidence that every tray and trolley is ready on time, every time.

What is an utensils washing machine?

An utensils washing machine is an equipment designed specifically to wash kitchen tools, trays, trolleys, and other items that your staff handle every day. In busy kitchens or food production facilities, these items move fast, get dirty quickly, and need to be ready again without delay.

Why does it matter? Because hygiene isn’t optional. Contaminated utensils can slow production, compromise food safety, and put your business at risk. A good utensils washing machine ensures that every item is washed thoroughly, consistently, and safely, without extra effort from your staff.

Think of it as keeping the engine of your operation running smoothly: when utensils are reliably washed and ready, your team can focus on cooking, preparing, or processing, rather than worrying about washing, re-washing, or managing last-minute shortages.

Benefits of an utensils washing machine

Investing in the right utensils washing machine makes daily operations safer and more predictable. Here’s why it’s a game-changer for any busy kitchen or food processing facility.

1. Consistent hygiene

No more wondering if every tray, trolley, or utensil is properly sanitized. A quality machine ensures consistent washing and disinfection, reducing the risk of contamination and keeping your staff and customers safe.

2. Time and labour savings

Manual washing can slow down your workflow and tie up valuable team members. With an automated washing solution, utensils are washed faster and with less effort.

3. Versatility for all types of equipment

From trays and bins to delicate utensils, the best machines adapt to different shapes and materials. One machine can handle multiple needs, eliminating the hassle of separate washing solutions.

4. Reliability under pressure

In busy periods, every minute counts. A dependable utensils washing machine keeps up with your operation’s pace, ensuring you never run short of washed equipment when you need it most.

5. Operational efficiency

Beyond sanitation, the right machine optimizes water, energy, and detergent use. This translates to lower operating costs and a more sustainable, streamlined workflow.

Limitations of an utensils washing machine to keep in mind

Even the best utensils washing machines have their limits. They can handle a wide range of equipment, but extremely large or oddly shaped items may not fit properly, requiring additional manual washing.

Maintenance and upkeep are essential. Filters, jets, and heating elements need regular attention to maintain performance. Neglecting this can reduce washing quality and shorten the machine’s lifespan.

Finally, initial investment and space requirements can be significant. Choosing a machine that’s too large or too small for your operation can affect both budget and workflow efficiency, so careful planning is crucial.

How to choose the ideal utensils washing machine

Choosing the right utensils washing machine is finding a solution that fits your operation’s rhythm, your team’s needs, and your hygiene standards. Here’s a step-by-step approach to make a confident choice.

1. Understand your workflow

Start by mapping how utensils move through your operation. Which items need washing most frequently? Are there peak periods where demand spikes? Understanding your workflow ensures you choose a machine that can handle your busiest hours without causing delays.

2. Assess the types of utensils and equipment

Consider the shapes, sizes, and materials of the trays, trolleys, and utensils you use daily. The right machine will accommodate your mix without compromising washing quality or risking damage.

3. Define capacity and throughput needs

Calculate the volume of items that need washing per shift. Too small a machine creates holdups; too large, and you waste energy and space. Match the machine’s capacity to your realistic operational demands.

4. Evaluate washing performance

Look beyond the surface. Can the machine remove stubborn residues, grease, and frozen food particles effectively? Check for high-temperature cycles, adjustable jets, or specialized programs. These features make a tangible difference in hygiene and safety.

5. Check ease of use and maintenance

A technically advanced machine is useless if it slows your team down. Opt for intuitive controls, quick loading and unloading, and simple maintenance routines. Reliability depends on your staff being able to operate and maintain it without stress.

6. Consider energy efficiency and sustainability

Modern machines can save significant water, energy, and detergent, reducing operating costs. Of course that being green is paramount, but it’s also important to make your operation leaner and more predictable.

7. Plan for integration in your space

Think about where the machine will sit. It should fit seamlessly into your kitchen or production line, supporting your workflow rather than forcing workarounds or extra handling.

8. Evaluate Total Cost of Ownership (TCO)

Price is only one part of the picture. Consider installation costs, energy consumption, maintenance, and potential downtime. A machine with a higher upfront cost can pay off quickly if it’s reliable, efficient, and reduces manual labour. And that gives you better value over time.

Choose an utensils washing machine wisely with MultiWasher

In real kitchens and food production facilities, every minute counts, and every tray, trolley, or utensil that isn’t ready on time can create bottlenecks, stress your team, or even compromise hygiene. The good news is… MultiWasher can make a tangible difference.

MultiWasher is designed with the realities of busy operations in mind. It can handle a diverse range of equipment, from large trays and trolleys to smaller utensils, without compromising washing quality. Energy and water efficiency further support operational savings, meaning the machine contributes not only to hygiene and speed but also to smarter resource management.

For anyone who values efficiency, consistency, and safety in their kitchen or production line, MultiWasher offers a practical, reliable solution that truly fits the way you work. Get in touch.

You may also like

Industrial washing / Articles

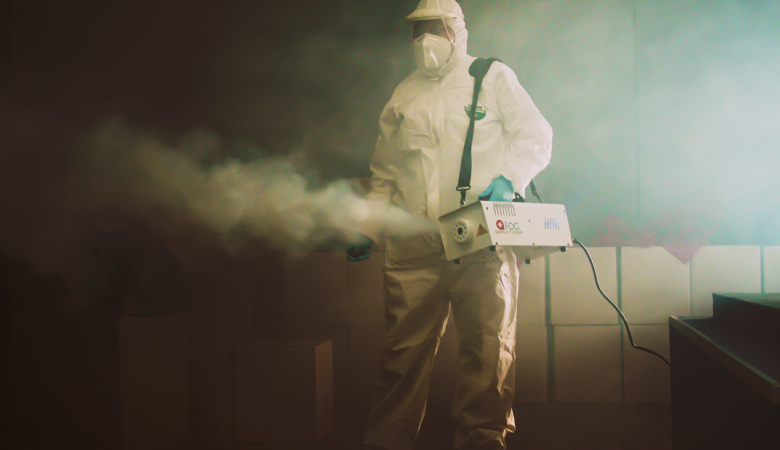

Sanitization: what is it and why is it important?

Sanitization is key to public health. Find out what it means and how it may avoid disease outbreaks in your company.

Posted in 2022-06-17

Industrial washing / Articles

Washing system: how to increase efficiency

An effective washing system has a direct impact on key management indicators and can represent significant savings. Find out how.

Posted in 2022-02-17

Portugal

Portugal United Kingdom

United Kingdom United States

United States France

France Spain

Spain Germany

Germany Romania

Romania Italy

Italy Czech Republic

Czech Republic Finland

Finland Hungary

Hungary Slovakia

Slovakia Greece

Greece Lithuania

Lithuania South Korea

South Korea Russia

Russia Saudi Arabia

Saudi Arabia Poland

Poland Brasil

Brasil Hebrew

Hebrew