Industrial washing / Articles

Sonae and MultiWasher: case study in sustainable retail transformation

MultiWasher was the solution chosen by Sonae to eliminate the need for manual sanitization. Discover the results.

3 minutes of reading

3 minutes of reading

2024-01-05 09:47:00

Sonae is a multinational business group, present in 90 countries and operating in various sectors. Retail, financial services, shopping center management, software and information systems, media and telecommunications are some of the most important business areas. In retail alone, Sonae has more than 100 stores throughout the country, distributed in various brands such as Continente, Modalfa and Wells. They chose MultiWasher to increase the efficiency of their operations and save resources such as water and energy. This is their journey with our machine.

The problem

Before Multiwasher, the sanitizing of utensils, tools and objects in Continente stores was carried out manually in specific stalls or directly on the floor, compromising the safety of the processes.

In addition, this type of sanitizing required repetitive and injury-prone movements, as well as long periods of time in contact with water and chemicals. As a result, it took 23 hours to wash utensils and work tools per day and store, and workers dedicated around 53% of their working time to these sanitizing tasks.

MultiWasher was chosen by Sonae to eliminate the need for manual cleaning. The result was a 74% time saving in washing utensils and work tools, such as trays, trolleys, bakery screens, chicken roaster grills, suckling pig trays, replacement trolleys, shopping baskets, among others.

The high temperatures of 85ºC safeguard the quality of sanitization, both in terms of efficiency and the elimination of the microbial load, which is crucial to guaranteeing food safety. MultiWasher can also export daily reports, from the number of uses to the consumption of water, detergent and energy, in order to measure real resource savings.

The results

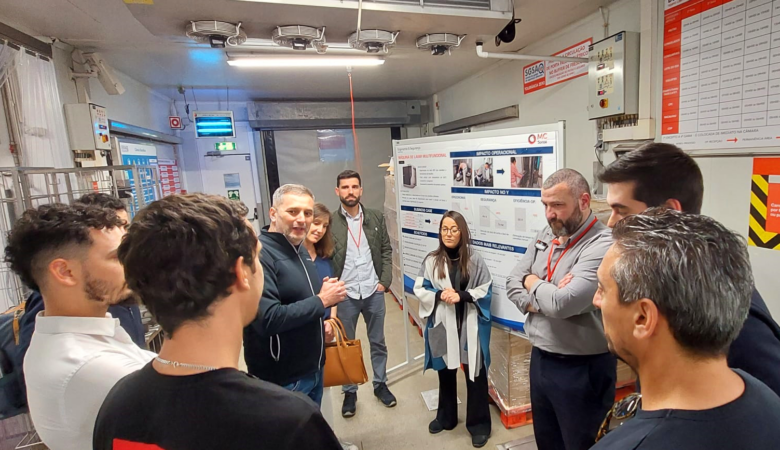

Thirty-day tests were carried out in two stores to assess the quality and efficiency of MultiWasher. The results showed very significant improvements in all parameters.

Ergonomics

- Continuous reduction/elimination of critical postures: -60%

Safety

- Reduction in the risk of cuts: -40%

Operational efficiency

- Elimination of manual utensil washing time: -74%

In addition to these numbers, the MultiWasher delivered:

- 76% water saving.

- Savings of 19% on detergent.

- Less degradation of equipment.

- Less degradation of uniforms and personal protective equipment.

MultiWasher, the industrial washing solution for retailers

MultiWasher raises the standards of cleanliness, efficiency and sustainability, redefines the sanitizing experience, and gives retailers a competitive edge. Get in touch, watch this machine in action and see for yourself the impact it can have on your washing results and resource efficiency.

You may also like

Industrial washing / Articles

“Pressures on sustainability are increasing - but they can also drive innovation.”

André Quental explains how sustainability pressures can also power innovation.

Posted in 2024-08-29

Portugal

Portugal United Kingdom

United Kingdom United States

United States France

France Spain

Spain Germany

Germany Romania

Romania Italy

Italy Czech Republic

Czech Republic Finland

Finland Hungary

Hungary Slovakia

Slovakia Greece

Greece Lithuania

Lithuania South Korea

South Korea Russia

Russia Saudi Arabia

Saudi Arabia Poland

Poland Brasil

Brasil Hebrew

Hebrew