Industrial washing / Articles

The hidden cost of foodborne illnesses to your business

Ignoring the risks of foodborne illnesses can cost a lot more than you think. Find out how MultiWasher can protect your operation - and your reputation.

11 minutes of reading

11 minutes of reading

2025-05-09 14:45:19

The World Health Organization estimates that around 1 in 10 people globally fall ill due to foodborne illnesses each year. With serious health consequences, product recalls, damaged reputations, and legal headaches that can spiral quickly out of control, they’re a real and present risk in any environment where food is handled, processed or served. Discover the true cost of overlooking food safety, and how you can turn your washing process into one of your strongest lines of defence.

What are foodborne illnesses?

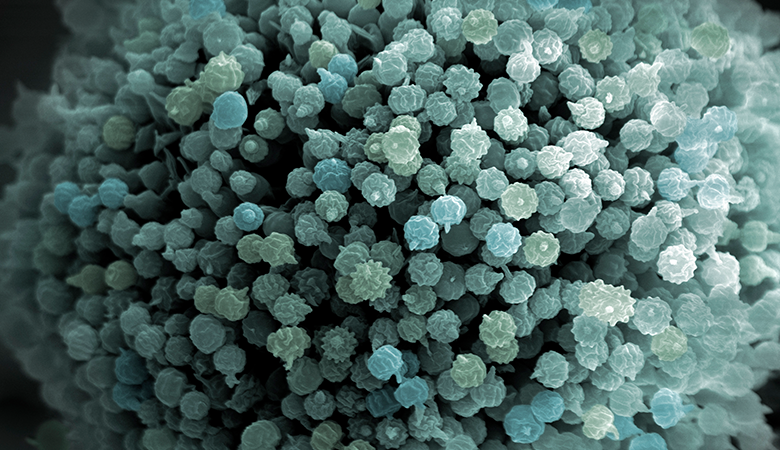

Foodborne illnesses occur when harmful bacteria, viruses, parasites, or chemicals sneak into our food and make us sick. They can be caused by anything from undercooked meat to cross-contaminated surfaces or even just improper storage. And while many cases are mild and go away on their own, some can be serious — especially for children, the elderly, or people with weakened immune systems. And in food production or food service environments, it only takes one hygiene slip-up to set off a chain reaction that could compromise an entire batch.

Foodborne illnesses usually stem from a handful of common mistakes or oversights in how food is handled, processed, or stored. Here are the main culprits behind most outbreaks:

- Poor personal hygiene: When food handlers don’t wash their hands properly or work while sick, they can easily spread harmful bacteria and viruses to the food.

- Cross-contamination: This happens when pathogens from raw meat, seafood, or unwashed produce come into contact with ready-to-eat foods via cutting boards, utensils, or surfaces that haven’t been properly cleaned.

- Improper cooking temperatures: Undercooked foods, especially poultry, eggs, and meat, may not reach the temperatures needed to kill bacteria like Salmonella or E. coli.

- Inadequate refrigeration or storage: Leaving food at unsafe temperatures (between 5°C and 60°C) gives bacteria the perfect environment to multiply rapidly.

- Contaminated water or raw materials: Using water that isn’t clean for washing or processing food, or working with ingredients that are already contaminated, can introduce pathogens at the very start of the chain.

- Failure to clean equipment properly: Food residue left on trays, tools, or machines can become a breeding ground for bacteria. Without thorough washing and disinfection, contamination can persist from one batch to the next.

What causes foodborne illnesses?

Foodborne illnesses come in various forms, each caused by different pathogens or contaminants. The most common culprits are bacteria, viruses, parasites, and toxins, each bringing their own set of challenges.

Bacterial infections

These are among the most prevalent foodborne illnesses. Pathogens like Salmonella, Escherichia coli (E. coli), Listeria monocytogenes, Campylobacter, and Clostridium perfringens are often responsible. They can contaminate a variety of foods, including raw or undercooked meats, unpasteurized dairy products, and fresh produce. Symptoms typically include diarrhea, abdominal cramps, and fever.

Viral infections

Viruses such as Norovirus and Hepatitis A can spread through contaminated food and water. Norovirus is particularly notorious for causing outbreaks in settings like cruise ships and restaurants. These infections often lead to symptoms like nausea, vomiting, and diarrhea.

Parasitic infections

Parasites like Toxoplasma gondii and Trichinella spiralis can be transmitted through undercooked meat or contaminated water. While some infections may be mild, others can lead to serious health complications, especially in vulnerable populations.

Toxin-related illnesses

Certain bacteria produce toxins that can cause illness even if the bacteria themselves are no longer present. For example, Staphylococcus aureus and Clostridium botulinum produce toxins that can lead to food poisoning. These toxins can be present in improperly stored or preserved foods.

The hidden costs of foodborne illnesses for businesses

Overlooking the risk of foodborne illness can trigger a chain reaction that no business wants to deal with. And unfortunately, the consequences tend to hit hard.

Putting health at risk

The most immediate and serious consequence of poor hygiene is the risk to human health. Foodborne pathogens like Salmonella, Listeria, or E. coli can cause anything from nausea and vomiting to severe infections, organ failure, or even death in extreme cases. Vulnerable groups — such as children, the elderly, pregnant women, and immunocompromised individuals — are especially at risk. In an industrial setting, even a single oversight can affect hundreds of people across the supply chain.

Damaging your reputation

Trust is fragile in the food industry. One contamination incident, and suddenly your business is in the spotlight — for all the wrong reasons. Customers might turn away, retailers may pull products from shelves, and suppliers could rethink partnerships. Even if the issue is resolved, the stigma often lingers. It's about showing, consistently, that hygiene is non-negotiable.

Facing regulatory consequences

Food safety authorities don’t take contamination lightly. Depending on the jurisdiction and severity of the incident, businesses may face inspections, fines, or even forced shutdowns. Non-compliance with HACCP, ISO, or local regulations can lead to revoked certifications, disrupted operations, and long-term costs that far outweigh the price of prevention.

Absorbing unexpected costs

A foodborne illness outbreak often means more than just a recall. There's product waste, halted production, legal fees, compensation claims, and the need for deep washing or equipment replacement. These hidden costs can snowball quickly. Automating and optimising washing processes with reliable, high-performance equipment helps prevent these surprises and keeps operational budgets under control.

Undermining team morale

Finally, internal culture can take a hit. When a business is caught in a hygiene scandal, it affects not just customers, but staff too. Employees may feel anxious, demotivated or blamed — especially if they haven’t been given the right tools or training to work safely.

How to prevent foodborne illnesses?

Preventing foodborne illnesses in industrial food environments requires more than just good intentions — it demands precision, consistency and the right tools. Here’s how to create a food safety system that truly holds up under pressure.

Maintain personal hygiene

Every food safety programme begins with people. Asides from washing hands thoroughly and frequently, use protective gear such as gloves, hairnets, and masks should be worn when necessary and changed frequently. Importantly, staff with symptoms of illness, particularly gastrointestinal, should be kept away from food production areas. This human layer of protection forms the first barrier against microbial transmission.

Ensure safe food storage

Temperature control is one of the most effective ways to reduce microbial growth. Raw ingredients and perishable items should be stored below 5°C, while hot foods should be kept above 60°C — the so-called “danger zone” in between allows bacteria like Listeria and Salmonella to multiply rapidly.

Cook food properly

Thermal inactivation of pathogens requires food to be cooked to specific core temperatures — for example, poultry to at least 75°C, minced meats to 70°C, and fish to 63°C. Relying on colour or texture is not precise enough in industrial contexts. In large-scale kitchens or food manufacturing, consistent cooking temperatures must be monitored and logged for audit and traceability purposes.

Prevent cross-contamination

Cross-contamination can occur at any point in the food chain — especially when raw and ready-to-eat foods come into contact through shared surfaces, tools or personnel. The use of colour-coded utensils and work zones is essential. But even more critical is the hygiene of reusable equipment like trays, trolleys, bins and tools.

Wash equipment and utensils thoroughly

Residual food particles are a breeding ground for bacteria, and if not properly removed, they can lead to biofilm formation — a persistent and invisible threat. Industrial cleaning must go beyond visual hygiene.

Use safe water and raw materials

The quality of the water used for washing food, cleaning surfaces, and operating equipment must meet potable standards. Water sources should be regularly tested for microbial and chemical contaminants. Similarly, raw materials should only be sourced from certified suppliers with strong traceability systems in place. If the input materials are compromised, the entire chain is at risk.

Train staff regularly

Hygiene protocols are only as good as the people who apply them. Ongoing training ensures that employees understand not just the "how", but the "why" behind every safety measure. Topics should include food safety hazards, critical control points (HACCP), proper washing and sanitising procedures, and equipment handling.

Protect your business from foodborne illnesses with the Multiwasher

When it comes to food safety, there’s no room for “almost clean” or “good enough.” The consequences of overlooking hygiene — from health risks to legal and reputational fallout — are simply too serious. That’s why relying on manual processes or outdated equipment just doesn’t cut it anymore. Designed for industries where hygiene is non-negotiable, MultiWasher ensures every utensil, tray or tool is thoroughly washed, sanitised and ready to use again — safely. With programmable cycles, energy-efficient systems and full technical support from the Somengil team, you don’t just get a machine. Let’s talk.

You may also like

Industrial washing / Articles

Commercial kitchens: the 10 steps to achieve max efficiency

Discover 10 proven steps to maximize efficiency in your commercial kitchen, saving time, reducing costs, and improving hygiene.

Posted in 2025-02-04

Industrial washing / Articles

How to choose cage washers

If you’re not using a cage washer yet, it’s time to level up and let automation take over. Discover how it works and how to choose one.

Posted in 2024-11-29

Portugal

Portugal United Kingdom

United Kingdom United States

United States France

France Spain

Spain Germany

Germany Romania

Romania Italy

Italy Czech Republic

Czech Republic Finland

Finland Hungary

Hungary Slovakia

Slovakia Greece

Greece Lithuania

Lithuania South Korea

South Korea Russia

Russia Saudi Arabia

Saudi Arabia Poland

Poland Brasil

Brasil Hebrew

Hebrew