Industrial washing / Articles

How to set hygiene standards for your company

Learn how to set hygiene standards for your company with practical tips, from identifying risks to choosing the right tools.

10 minutes of reading

10 minutes of reading

2025-02-13 17:36:07

Back in 2014, a scandal rocked the UK’s food industry to its core. The cause? Chickens. Not the birds themselves, but what was lurking on them – "campylobacter", a bacteria responsible for food poisoning. Shockingly, up to eight in ten supermarket chickens carried traces of this potentially deadly pathogen, a revelation that sent the public into a frenzy and experts calling for outright boycotts. Supermarkets scrambled for damage control, issuing statements about “leak-proof packaging” and “roast-in-the-bag chickens.” But the damage was done – confidence in hygiene standards plummeted, leaving shoppers second-guessing their dinner choices.

Fast forward to today, and the dirty chicken scandal serves as a powerful reminder: hygiene is the cornerstone of trust. When contamination levels are scandalous enough to make national headlines, it’s clear that neglecting hygiene can tank reputations, devastate industries, and endanger lives.

However, achieving the balance between spotless standards and practical efficiency isn’t always straightforward. So, how do you set hygiene standards for your company that truly work? Let’s break it down into actionable steps.

1. Define your hygiene objectives

Before diving into protocols and equipment, you need clarity on what “hygiene” looks like for your specific operations. Hygiene goals aren’t one-size-fits-all. They can vary dramatically depending on your industry and the nature of your business. Start by reviewing regulatory requirements in your sector. For example, in food production, eliminating bacteria and allergens is non-negotiable. In pharmaceutical labs, the focus is on sterility while in hospitality, maintaining spotless utensils is key to customer trust.

2. Identify high-risk areas

Once you understand the basics, consider the unique needs of your operation. Not all areas in your operation have the same hygiene requirements. High-risk zones require extra attention, such as places or equipment that come into direct contact with sensitive materials or that are more likely to harbour bacteria. Identifying these areas early on can help you prioritize resources and set more effective washing protocols.

- Do you deal with materials prone to contamination?

- Are there seasonal fluctuations in demand that require heightened washing during peak periods?

- Which surfaces or tools come into direct contact with food, chemicals, or other sensitive materials?

- Are there spots prone to moisture buildup, like sinks, drains, or equipment with hard-to-reach crevices?

- Do certain areas experience higher traffic, such as employee workstations or packaging zones?

For example, in a bakery, mixing bowls, countertops, and rolling pins are prime high-risk areas because they come into contact with raw ingredients like eggs and flour, both of which can carry harmful bacteria. Similarly, in a laboratory, glassware and pipettes used in chemical analysis must be meticulously washed to prevent contamination.

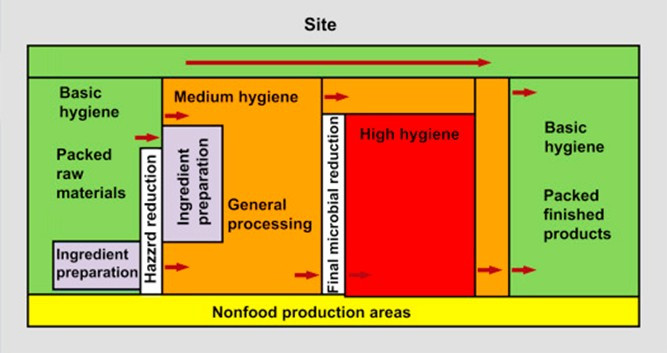

3. Create a visual hygiene map of your facility

It helps to have a visual hygiene map of your facility:

- Mark high-risk areas in red to denote where frequent and thorough washing is essential.

- Use yellow for moderate-risk zones, like storage shelves.

- Highlight low-risk areas, such as office spaces, in green to ensure you don’t overallocate resources.

Visual hygiene map example

Once high-risk areas are identified, tailor your washing schedule accordingly. For instance, for high-risk zones, wash after every use or every shift, and for moderate-risk zones, wash once daily. For low-risk zones, wash weekly or as needed.

Quick tip:

Don’t forget to include employee touchpoints like handles, switches, and tools in high-risk zones. These often-overlooked areas can become breeding grounds for germs if not washed frequently.

4. Choose the right equipment

When it comes to maintaining hygiene standards, the tools you use are as important as the protocols you establish. Cutting corners with subpar equipment not only risks compliance issues but also impacts efficiency and costs. Investing in the right washing technology – like industrial-grade solutions – can elevate your hygiene processes while saving time and resources.

Manual washing methods are often inconsistent, prone to human error, and time-consuming. For businesses dealing with large volumes of equipment or strict hygiene requirements, these methods fall short. The right washing equipment ensures:

- Thorough sanitation: Removes dirt, grease, and bacteria in every cycle.

- Time efficiency: Handles more in less time, freeing up staff for other tasks.

- Consistency: Delivers a uniform wash every time, leaving no room for guesswork.

MultiWasher stands out as a game-changer for industrial hygiene. Designed for heavy-duty washing, it accommodates various types of equipment, from utensils and trays to tools and containers. Here’s why it’s a must-have:

- Versatility: Handles gastronorm containers as easily as robust machinery parts.

- Eco-efficiency: Uses less water and energy compared to traditional washing systems, making it a sustainable choice.

- Automated precision: Features programmable cycles tailored to different washing needs, ensuring that every item meets hygiene standards.

- Reliability over the long term: It’s easy to maintain and come with robust support.

5. Train your team like pros

Even with the best equipment and the most detailed hygiene protocols, your efforts will fall short if your team isn’t on board. Training is the linchpin that ensures everyone understands, implements, and maintains your hygiene standards. The goal is to turn your employees into hygiene defenders who take pride in keeping your operation spotless.

A well-trained team can identify hygiene risks before they become issues, operate washing equipment correctly and efficiently, and maintain consistency in washing routines, even under pressure.

Creating an engaging and practical training program doesn’t have to be daunting. Here’s how to structure it:

- Start with the basics. Begin by explaining why hygiene matters for your business. Link it to real-world consequences, like customer trust, regulatory fines, or product recalls. Use visuals, such as before-and-after washing examples or case studies of hygiene failures in your industry.

- Hands-on equipment training. Theory is important, but practice is what makes it stick. Our support service includes training our team on the proper use of MultiWasher. We cover essential topics such as selecting the right washing cycle for different items, loading and unloading the washer to prevent damage or missed spots, and performing routine maintenance checks to ensure the machine operates at peak efficiency.

- Create cheat sheets and visual aids. Not everyone retains information the same way. Provide easy-to-understand guides that employees can reference on the job.

6. Monitor, evaluate, and improve

Setting hygiene standards is an ongoing process. Even the most well-thought-out protocols need regular monitoring and updates to keep up with evolving industry standards, technological advancements, and the changing needs of your business. By creating a system for continuous improvement, you ensure your hygiene practices stay sharp, effective, and compliant.

Here’s how to monitor hygiene standards effectively:

- Conduct routine inspections. Schedule regular walkthroughs of your facility to check if washing protocols are being followed. Inspections can include visual checks on equipment and surfaces, spot testing to ensure bacteria or residue levels meet standards or observing how employees handle washing processes, such as operating equipment or sanitizing tools.

- Use data for insights. If you’re using advanced washing equipment like MultiWasher, take advantage of its data-tracking capabilities. Many industrial machines record cycle performance, water usage, and washing times. Analyse this data to pinpoint areas for improvement.

- Gather employee feedback. Your team works on the front lines and often has the best insights into what’s working and what isn’t. Encourage open communication by creating channels for feedback.

- Set key performance indicators (KPIs). Track measurable KPIs to assess how well your hygiene practices are performing. Examples may include time efficiency (average time taken to wash all equipment per shift), compliance rates (percentage of items passing tests on the first inspection) or equipment utilization (percentage of washing equipment capacity used efficiently).

Set hygiene standards and elevate your business

Setting hygiene standards is an investment in your company’s future. Washed equipment leads to safer products, happier customers, and a stellar reputation. With MultiWasher by your side, achieving these standards becomes more than manageable: efficient and cost-effective.

Are you ready to transform hygiene in your company? Because spotless results are just a MultiWasher cycle away. Get in touch today.

You may also like

Industrial washing / Articles

5 key trends from Anuga 2024

We were at Anuga, one of the major fairs in the food sector worldwide. Discover the 5 main trends that will shape the upcoming years.

Posted in 2024-05-07

Industrial washing / Articles

Commercial kitchens: the 10 steps to achieve max efficiency

Discover 10 proven steps to maximize efficiency in your commercial kitchen, saving time, reducing costs, and improving hygiene.

Posted in 2025-02-04

Industrial washing / Articles

Sanitization: what is it and why is it important?

Sanitization is key to public health. Find out what it means and how it may avoid disease outbreaks in your company.

Posted in 2022-06-17

Portugal

Portugal United Kingdom

United Kingdom United States

United States France

France Spain

Spain Germany

Germany Romania

Romania Italy

Italy Czech Republic

Czech Republic Finland

Finland Hungary

Hungary Slovakia

Slovakia Greece

Greece Lithuania

Lithuania South Korea

South Korea Russia

Russia Saudi Arabia

Saudi Arabia Poland

Poland Brasil

Brasil Hebrew

Hebrew