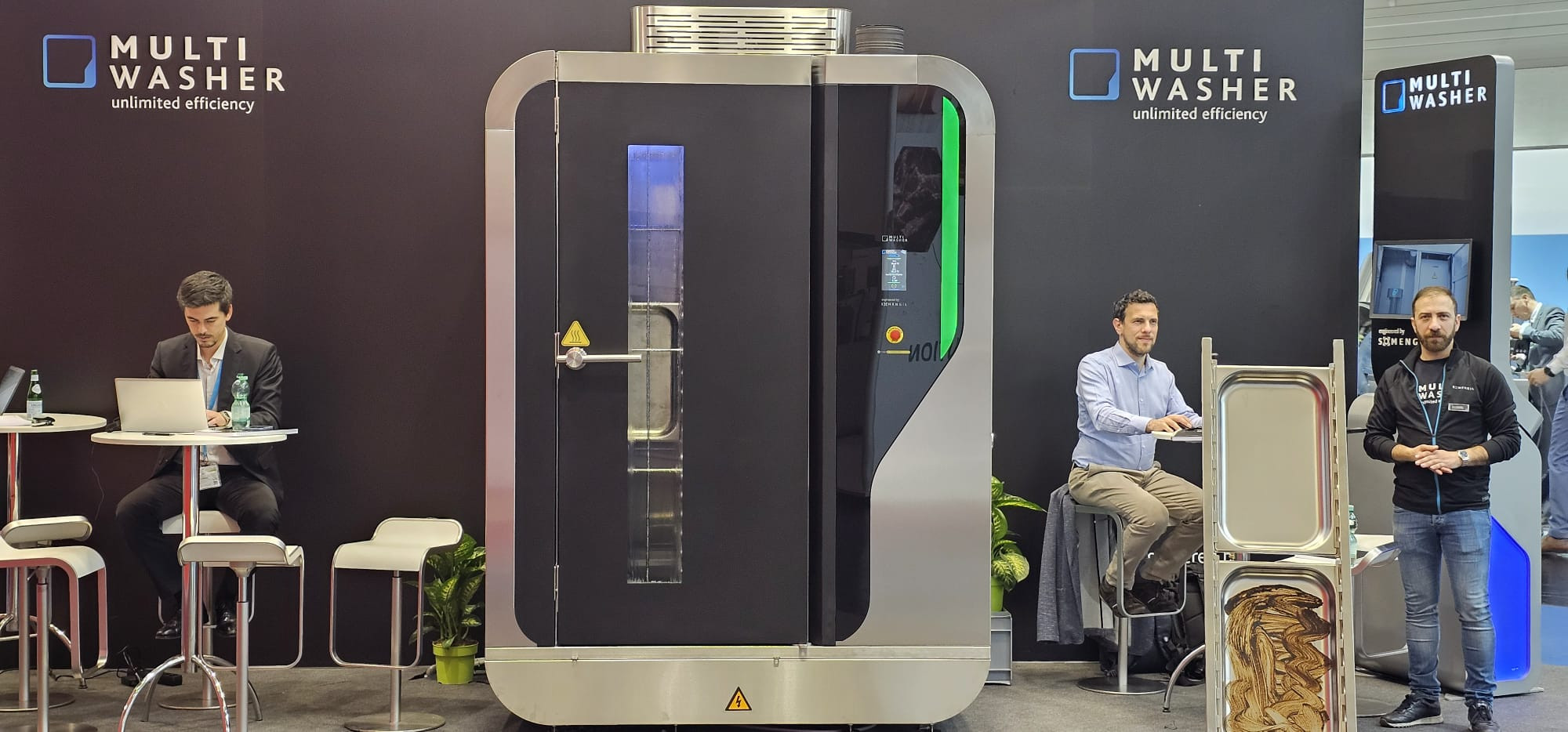

Une solution de lavage innovante

Multiwasher a été élaborée sous forme de cabine, ce qui permet un contrôle total des cycles de lavage.

Au delà de sa technologie de pointe, qui permet un lavage efficace et durable, Multiwasher emploie des processus optimisés qui garantissent une désinfection impeccable ainsi que des économies d'énergie et de ressources.

Design et adaptabilité

L’adaptabilité de Multiwasher permet le développement de solutions personnalisées et adaptées à chaque client. Pour plus de flexibilité, plusieurs ustensiles et objets différents peuvent être intégrés au cours du même cycle de lavage.

Des secteurs variés

Multiwasher a été conçue de façon à constituer une solution de lavage efficace pour tous les secteurs de l’industrie. Avec son système de chariots de lavage et de programmes élaborés en fonction des objets à laver, la qualité et l’optimisation du lavage sont garanties.

Ils nous font déjà confiance

Rejoignez-les !

2000 équipements dans plus de 30 pays.

La satisfaction de nos clients est la preuve que nous travaillons dur pour vous proposer la meilleure expérience possible. De la compétence de nos ingénieurs, en passant pas notre méthode de vente consultative, à l’installation et le service après-vente, tout a été pensé pour vous donner entière satisfaction.

Portugal

Portugal United Kingdom

United Kingdom United States

United States France

France Spain

Spain Germany

Germany Romania

Romania Italy

Italy Czech Republic

Czech Republic Finland

Finland Hungary

Hungary Slovakia

Slovakia Greece

Greece Lithuania

Lithuania South Korea

South Korea Russia

Russia Saudi Arabia

Saudi Arabia Poland

Poland Brasil

Brasil Hebrew

Hebrew