Lavagem Industrial / Artigos

Multiwasher: Revolutionizing sanitation in the food industry

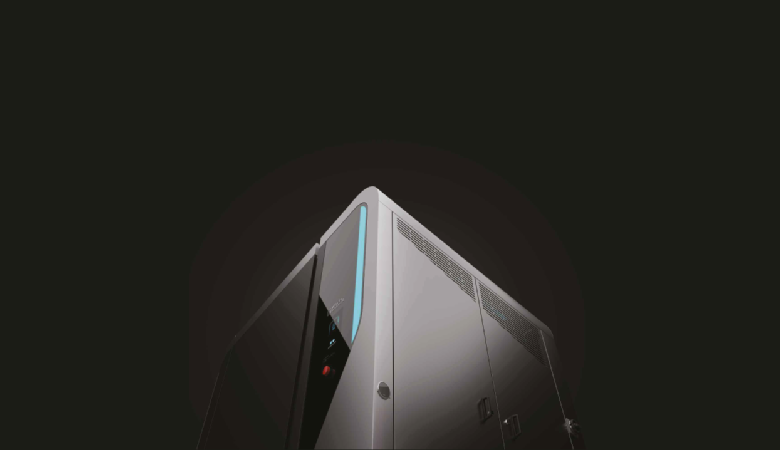

The Multiwasher is the world’s most innovative industrial washing machine that is increasing sanitation across many industries.

3 minutos de leitura

3 minutos de leitura

2023-05-03 19:26:14

Luc Imberechts – CEO Bakon USA

Connor Freeman – Industry Specialist

Background

The Multiwasher is the world’s most innovative industrial washing machine that is increasing sanitation across many industries. This state-of-the-art equipment ensures hygienic washing and disinfection of any industrial utensil or equipment while meeting all efficiency, sustainability, and safety requirements. An industrial washing machine combines biodegradable detergents with water at high temperatures (over 65ºC), to eliminate residues of fat, waste, germs and bacteria; thus the Multiwasher contributes to greater food safety when compared to traditional manual processes.

Sanitation

Sanitization relies on special equipment and chemicals to fight viruses and bacteria. Even after intensive cleaning, harmful microorganisms may still be present on surfaces, causing allergies and respiratory diseases such as bronchitis, asthma, rhinitis – or worse. But sanitization also contributes to better conservation of food, since, without the deterioration caused by bacteria, products gain a longer shelf life. When choosing an industrial washing machine, the temperature at which it operates is critical. High temperatures ensure complete hygiene by eliminating organisms. Best practices in the food industry area, especially on the catering sector, state that companies should wash dishes and other utensils at a temperature between 80 to 90 degrees Celsius or 176 to 194 Fahrenheit.

How can we measure cleanliness?

The quality of washing is a fundamental decision factor and is measured using a luminometer to show the amount of light generated by adenosine triphosphate (ATP). This energy source is present in animal, plant, bacterial and fungal cells. The smaller the amount of light generated by an utensil, the cleaner it will be.

There are reference values for the light units generated by clean utensils in each industry: In the Food area, the maximum is 500 units of light. A result above this value shows an elevated concentration of organisms; In the Health sector, the requirements are naturally tighter–disinfection of hospital medical consumables requires a maximum of 100 units of light (except in operating rooms, where it is even more restricted).

When you combine technology and innovation with the actual needs of industries, you get groundbreaking results.

Também pode gostar

Lavagem Industrial / ArtigosArtigos

Tony Ventura in an exclusive interview

New challenges, emerging technologies and a planet that needs everyone’s input.

Postado em 2023-08-04

Lavagem Industrial / ArtigosArtigos

More productivity, less waste: what OEE means and how it gets results

OEE is an essential metric to ensure equipment efficiency. But what does it mean, and how can managers use it to improve performance on the shop-...

Postado em 2021-09-23

Lavagem Industrial / ArtigosArtigos

Pallet washer machines: the essential guide

Discover everything you need to know about pallet washer machines – what they are, their advantages, how they work, and tips for choosing the rig...

Postado em 2024-10-10

Português

Português English (UK)

English (UK) English (USA)

English (USA) Français

Français Español

Español Deutsch

Deutsch