Gestão / Artigos

6 productivity KPI to track every day

Productivity KPIs are the pulsing heartbeat of innovative companies. Here are 6 that you should track every day.

7 minutos de leitura

7 minutos de leitura

2023-03-16 19:05:36

Big Data, Artificial Intelligence, Industry 4.0, 5G – the number of data sources at a company’s disposable has never been greater. When multiple complex processes are at play, however, it can be challenging to know which KPIs to prioritize, how to measure them, and how to turn that information into concrete improvement actions. These are 6 productivity KPIs you should track every day.

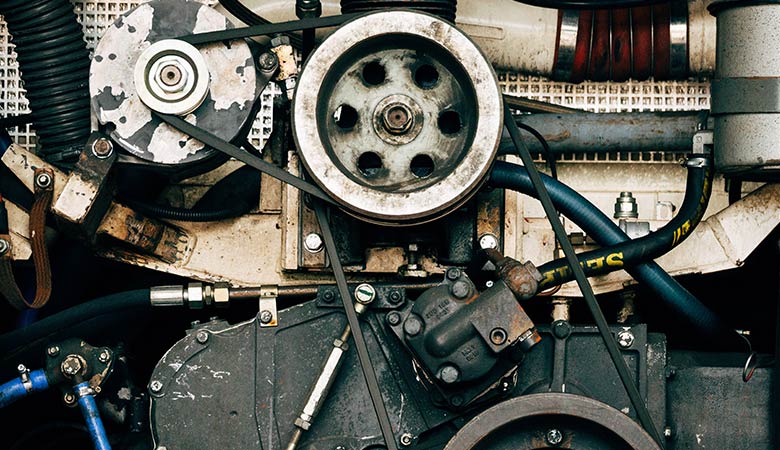

1. Overall Equipment Effectiveness (OEE)

This productivity indicator, known by its acronym OEE (Overall Equipment Effectiveness), is one of the most widely used to measure machine efficiency. In simple terms, it measures the percentage of manufacturing time that is productive. To calculate the OEE, you must consider 3 factors: Availability, Performance and Quality.

Availability considers the amount of planned and unplanned downtime. An Availability score of 100% means that the process is always running during the planned production time – setups, scheduled maintenance and mandatory break time are usually not included. Performance score, on the other hand, is affected by slow cycle times and short, unplanned stops or breakdowns. A score of 100% means that the process, when active, is running at standard speed.

Finally, the Quality factor considers defective products, including those that need rework. Achieving 100% on this sub-indicator means that only quality products are being produced, with no need for rework. Putting all the pieces of the equation together, a score of 100% for this KPI means the machine is always available, producing the maximum number of products without defects during a given period.

To improve this KPI, it is fundamental to count on efficient equipment and to perform maintenance routines as designed by the manufacturer. In the case of industrial washing, the MultiWasher is a leading washing machine, with several built-in functionalities to increase the OEE. For instance, it features several optimized programs to save time during setup. The intuitive dashboard allows you to quickly adjust settings and production parameters to ensure quality and performance.

2. Output per man-hour

This is one of the most widely used productivity indicators to gauge output capacity, especially in labor-intensive companies. To calculate it, simply divide the total goods produced by the total number of hours and workers involved. In logistics activities, for example, this KPI can be used to assess the productivity of picking activities, one of the most time-consuming processes. The same applies to the washing area, where this productivity KPI plays a key role.

Knowing how many utensils per hour one can wash with quality is one of the most important KPIs in this area. Machines like the MultiWasher were developed specifically with the purpose of improving this metric, reducing washing cycle times, and avoiding rework. To achieve this, the machine has been ergonomically designed to make it easier to introduce and remove the materials to be washed. This feature also increases the ability to wash a wide variety of products without having to adjust washing parameters.

3. Mean Time To Repair (MTTR)

This productivity indicator is especially important for maintenance teams. Mostly known by the acronym MTTR (Mean Time to Repair), it represents the mean time required to repair a malfunction and get the equipment back on and running at standard speed. This KPI can be calculated by dividing the total time spent in corrective maintenance by the total number of failures. The result is usually given in hours.

A high (or rising) MTTR may indicate that replacing equipment is preferable to repairing it. Managing this productivity indicator is essential to avoid or minimize downtime.

4. Capacity utilization

Capacity utilization relates the company’s current level of production activity to its maximum production potential. In other words, it compares how much the company produces against its maximum capacity and returns a simple percentage.

For example, if a company only produces 50% of its maximum potential, it means that it has the installed capacity to produce twice as much. In theory, these figures are presented considering an ongoing 24-hour production.

5. On-time deliveries

Known by the acronym OTD (On-Time Delivery), this KPI measures the number of deliveries to customers made on time. One simple way to calculate this KPI is to divide the number of late deliveries by the total number. For example, if you have 5 late deliveries in a week and 100 deliveries in total, OTD will be 95%.

A low OTD can indicate several upstream problems, either in planning, production, warehousing, or deliveries. This is thus an important overall productivity KPI to track and which summarizes the state of the organization. Some leading companies measure this indicator with a twist – the so-called OTD in full, which tracks not only on-time delivery, but also if the total quantity ordered was in fact delivered on time. If a single unit is missing, the delivery no longer counts as “on-time”.

6. Turnover

This is one of the most important productivity indicators for any company. It represents the turnover of employees within a company, i.e. how many people have left or joined in a given period. To calculate this KPI, simply use the average length of stay of each employee in the company. It can also be calculated by adding the number of resignations to the number of new admissions and then dividing by the total number of employees.

If the turnover rate is high, productivity is likely to suffer, since new employees require time and resources to adapt to work standards. In addition, it can signal leadership problems or a lack of appreciation of professionals, which in turn influences all other productivity indicators.

How Somengil helps companies get better results

The MultiWasher is a state-of-the-art washing machine designed to sanitize any type of utensils. Especially in areas where hygienization is a critical success factor, the MultiWasher ensures more productivity, better results and reinforcement of food safety processes. Contact our consultants and see for yourself the impact the MultiWasher can have on your company’s productivity.

Também pode gostar

Gestão / ArtigosArtigos

Supply chain analytics explained: what it is and why it matters

How to leverage Supply chain Analytics to plan and implement a more reliable process.

Postado em 2024-07-03

Gestão / ArtigosArtigos

One Step Ahead: What is Predictive Maintenance?

Predictive maintenance uses data to predict and prevent failures, increase equipment lifetime and improve efficiency. But what does it mean for b...

Postado em 2022-01-06

Gestão / ArtigosArtigos

Lean Manufacturing in the food industry: more than a buzzword

Lean Manufacturing helps companies in the food industry be more competitive and innovative. But why do so many companies struggle and what is the...

Postado em 2021-12-23

Português

Português English (UK)

English (UK) English (USA)

English (USA) Français

Français Español

Español Deutsch

Deutsch